Overhead Conveyor Systems: Enhancing Production Line Material Handling

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

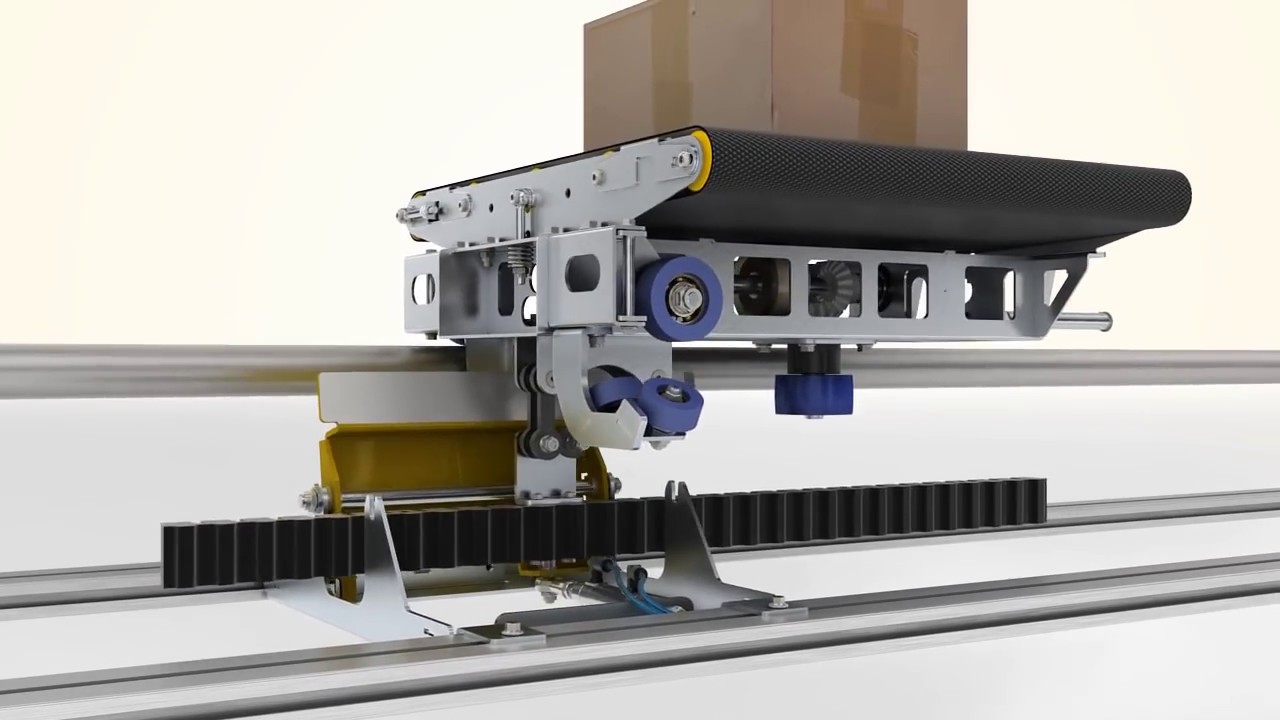

NIKO Overhead Conveyor Systems represent a classic yet highly effective mechanized automation solution for material handling within production environments. These systems utilize a network of tracks installed overhead, from which carriers or trolleys are suspended to transport materials, components, or products through various stages of a production or assembly line. By moving materials above the workspace, they free up valuable floor space for personnel, equipment, and other activities. NIKO positions its systems as precision-engineered solutions that deliver seamless functionality, aiming to enhance overall production line efficiency and workflow. This technology is foundational for creating connected, continuous-flow manufacturing processes, particularly in industries like automotive, apparel, and general manufacturing where items need to be moved between fixed stations.

How It Works

Core Principles

The core principle is Suspended, Fixed-Path Material Transport. Products are attached to carriers (hooks, baskets, fixtures) that hang from trolleys running on an overhead track. The track defines a fixed route through the facility. The trolleys are propelled along the track, typically by a continuous chain or cable, moving the suspended loads from one workstation to the next in a predetermined sequence.

Key Features & Capabilities

Precision Engineering for Reliability ensures smooth and consistent operation with minimal downtime, which is critical for maintaining production line节奏. This includes robust mechanical components and careful alignment.

Seamless Integration into Production Lines is a key design focus. The systems are built to interface with other equipment and human workstations, providing a steady, predictable flow of materials exactly where and when they are needed.

Overhead Space Utilization is the primary spatial advantage. By using the often-underutilized air space, these systems keep floors clear for safe personnel movement and other equipment, effectively increasing the usable capacity of a facility.

Advantages & Benefits

The primary benefit is Enhanced Production Line Efficiency and Flow. By automating the transport of materials between stations, overhead conveyors eliminate manual cart pushing or forklift traffic, reducing wait times and creating a more rhythmic, predictable production pace.

It Revolutionizes Workflow through Continuous Movement. The system enables a true assembly line approach, where products are constantly moving toward completion, which can significantly reduce total production cycle time compared to batch-and-queue methods.

The technology Optimizes Facility Layout and Safety. Keeping transport off the floor reduces congestion and separates material flow from pedestrian and vehicle traffic, enhancing overall workplace safety and organization.

It provides a Scalable Foundation for Automation. An overhead conveyor system can be the backbone to which other automation (like automated loading/unloading) is added over time, allowing for gradual modernization of the production process.

Implementation Considerations

Structural Requirements and Installation are significant. The ceiling or support structure must be capable of bearing the weight of the loaded conveyor system. Installation can be complex and may require production downtime.

Limited Route Flexibility is inherent. Once installed, the track path is fixed. Changes to the production layout or process flow may require physically re-routing the conveyor, which can be costly and disruptive.

Product Compatibility must be assessed. The products must be suitable for overhead suspension (e.g., have a point for hanging, not be overly fragile or imbalanced). The carrier design must match the product profile.

Conclusion

NIKO Overhead Conveyor Systems are a proven and effective technology for automating material transport in production and assembly line settings. They are ideal for manufacturing operations with a fixed sequence of processes, high volume, and a need to optimize floor space and workflow continuity. While less flexible than mobile robots, they offer high reliability, throughput, and seamless integration for dedicated routes. For businesses looking to establish a robust, efficient backbone for their production material flow, overhead conveyors remain a cornerstone automation solution. Success depends on thorough planning of the conveyor path in relation to the production layout and ensuring the building infrastructure can support the system.