Automated Vertical Storage Solutions

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

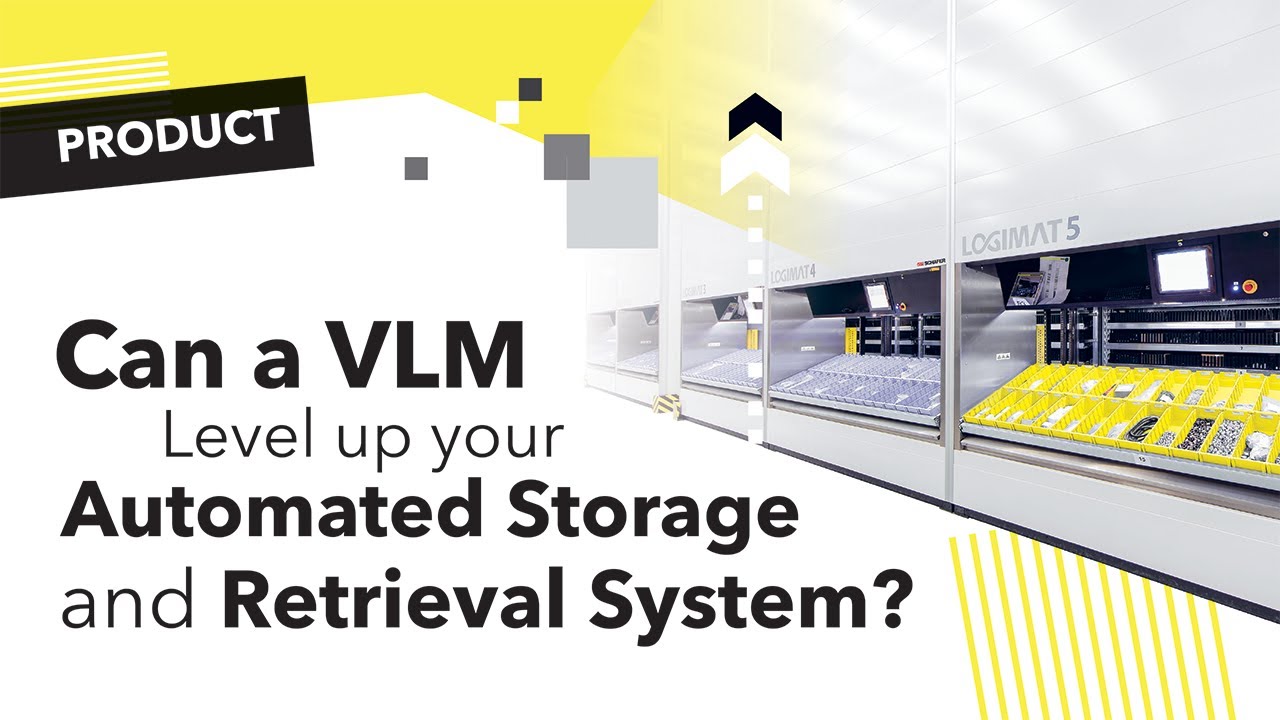

Modula Lift refers to a line of automated vertical storage solutions, specifically Vertical Lift Modules (VLMs), designed and manufactured by the Italian company Modula. With a history dating back to 1987, Modula has established itself as a leader in manufacturing excellence focused on innovation in warehouse automation. These systems are engineered to address the universal challenge of space constraints and inefficient storage in industrial and commercial settings. By storing items vertically in a compact footprint and automating the retrieval process, Modula Lift solutions transform how businesses manage their inventory of small parts, tools, documents, or components. Their core value proposition lies in dramatically reducing the floor space required for storage while simultaneously improving access speed and inventory accuracy, making them a versatile choice applicable across a wide spectrum of industries and operational environments.

How It Works

Core Principles

The system operates on the principle of vertical density and automated goods-to-person delivery. It consists of a series of trays stored within a tall, enclosed column. An automated inserter/extractor mechanism, controlled by software, retrieves the specific tray containing the requested item and delivers it to an ergonomic access window at the front of the unit, bringing the items directly to the operator.

Key Features & Capabilities

Universal Suitability for Any Industrial Sector is a foundational claim. The design and construction of Modula Lift systems are robust enough for heavy industrial use (e.g., automotive, aerospace) yet precise and clean enough for sensitive environments like pharmaceuticals or electronics, demonstrating broad adaptability.

Space Optimization through Vertical Storage is the primary physical feature. By utilizing vertical air space that is typically wasted, these systems can often condense the contents of multiple aisles of shelving into a single, compact footprint, freeing up valuable floor space for production or other activities.

Manufacturing Excellence and Long-Term Innovation underpins the product's reliability. With decades of experience, Modula emphasizes durable construction and continuous innovation in drive systems, software, and safety features, aiming to provide a long-lasting and reliable automation asset.

Advantages & Benefits

The most significant advantage is a drastic reduction in storage footprint and real estate costs. By storing vertically, companies can often reduce the floor space dedicated to storage by 50-90%, allowing for facility consolidation or reallocation of space to revenue-generating activities.

It delivers substantial improvements in operational efficiency and worker productivity. The goods-to-person principle eliminates walking, searching, and climbing, reducing pick times by up to 80% and allowing operators to focus on the value-added task of picking itself, rather than material handling.

The system provides enhanced inventory accuracy, security, and control. With software-controlled access and tracking of every transaction, inventory records are maintained in real-time. The enclosed structure also protects items from dust, damage, and unauthorized access.

Implementation Considerations

Adequate ceiling height is required to install the unit and fully benefit from its vertical storage capacity. Site surveys are necessary to ensure proper fit and structural support.

Effective tray configuration and slotting strategy are crucial for maximizing throughput. Planning how items are organized within the trays based on size, weight, and pick frequency directly impacts the system's efficiency and ergonomics.

While highly automated for retrieval, it is typically a single-point access system. For very high-throughput environments, multiple units or integration with conveyor systems to serve multiple workstations may be necessary.

Use Cases & Applications

Ideal For

This technology is ideal for manufacturing plants (for kitting and line-side supply), maintenance and tool cribs (MRO), distribution centers for small parts, healthcare facilities (medical supplies, pharmacy), and any operation managing a high variety of small to medium-sized items.

Performance Metrics

The content emphasizes qualitative performance gains: optimized warehouse efficiency and reduced space requirements. Key inferred metrics include a high percentage of floor space savings, reduced pick times, and improved inventory accuracy compared to manual shelving.

Conclusion

Modula Lift vertical storage solutions offer a proven and effective method for conquering space and efficiency challenges in warehouse and production environments. Their strength lies in a simple yet powerful concept: using vertical space to store more in less area and automating access to save time and reduce errors. For businesses struggling with cluttered storage areas, inefficient picking processes, or the high cost of industrial space, implementing a Modula Lift system can provide a rapid and tangible return on investment. With a long track record and focus on robust design, they represent a reliable automation choice. Success depends on proper sizing, thoughtful item slotting, and integrating the system into daily workflows. When deployed correctly, it becomes a cornerstone for organized, efficient, and space-conscious operations.