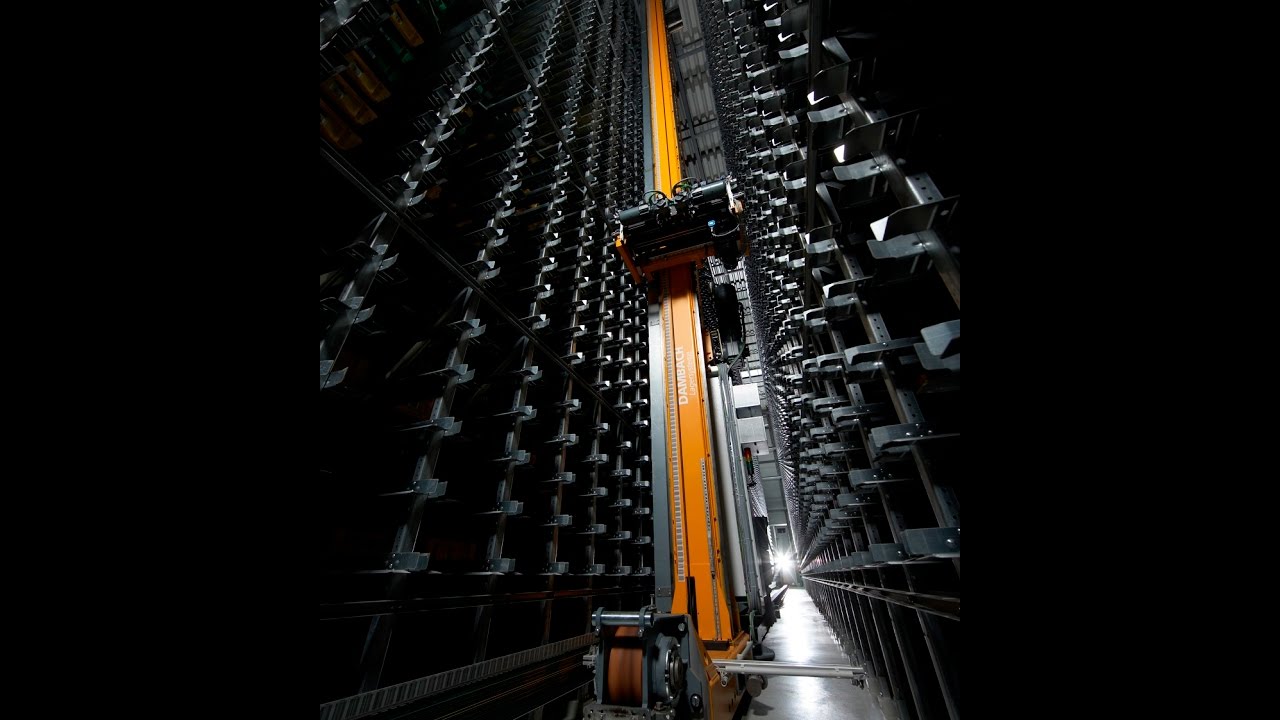

Miniload: High-Performance Stacker Crane

⚡Quick Facts

Technology Performance Metrics

⭐Key Features

✨Benefits

🎯Applications

📝Detailed Information

Technology Overview

The Jungheinrich STC 2B1A represents a high-end entry into the mini-load automated storage and retrieval system (ASRS) market, engineered for maximum operational efficiency. Developed by Jungheinrich, a major player in intralogistics, this stacker crane is positioned as the most powerful solution within its competitive class. It is designed to meet the demanding needs of modern, high-throughput warehouses that utilize mini-load systems for storing small unit loads like totes and cartons. The system distinguishes itself through a combination of superior performance metrics, advanced energy management, and a compact physical footprint. By focusing on power, efficiency, and space-saving design, the STC 2B1A aims to deliver optimal productivity and a strong return on investment for automated storage operations.

How It Works

Core Principles

The STC 2B1A operates on the standard mini-load ASRS principle: a computer-controlled, rail-guided stacker crane retrieves and stores loads within a narrow aisle of high-density racking. Its claimed superiority lies in the enhanced power and efficiency of its drive systems, control software, and mechanical design, which together enable faster cycle times and lower energy consumption per transaction.

Key Features & Capabilities

Best-in-Class Performance Values are the centerpiece of this system. While specific numbers are not provided, this claim suggests superior metrics in key areas such as acceleration, maximum travel speed, lifting speed, and cycle times, enabling it to handle more transactions per hour than comparable systems.

Smart Energy Management is an integrated feature designed to reduce the total cost of ownership. This system likely involves energy-efficient components, regenerative drives that recover energy during braking, and intelligent software that optimizes movement patterns to minimize power consumption without sacrificing speed.

Lowest Approach Dimensions in its Class refers to the compact design of the crane's structure where it interfaces with the storage racks. A smaller approach dimension allows for the storage racks to be placed closer together, potentially increasing the number of storage positions per aisle or allowing operation in spaces with very tight clearances.

Advantages & Benefits

The primary advantage is maximized warehouse operational efficiency. The combination of high speed, precision, and reliability translates directly into higher throughput, allowing the warehouse to process more orders or support faster production cycles with the same footprint.

It offers reduced operational costs through energy savings. The smart energy management system directly lowers electricity consumption, which is a significant ongoing cost for automated equipment, contributing to a better lifetime cost-effectiveness.

The space-optimized design increases storage density. The minimal approach dimensions mean the physical infrastructure (the crane) occupies less space in the aisle, which can be leveraged to install deeper racking or more storage levels, maximizing the use of the available cubic volume.

Implementation Considerations

While marketed as highly efficient, the specific application requirements must be evaluated. The "most powerful" designation may imply it is optimized for facilities with very high cycle rate demands; its benefits may be less pronounced in lower-throughput operations.

Implementing a system with claimed best-in-class performance may involve higher initial capital investment compared to standard mini-load cranes, necessitating a thorough ROI analysis based on expected gains in throughput and energy savings.

Integration with the broader warehouse management and control ecosystem remains essential. The crane's performance can only be fully realized if it is part of a well-designed system with efficient inbound/outbound processes and responsive software.

Use Cases & Applications

Ideal For

This system is ideal for distribution centers, manufacturing warehouses, or e-commerce fulfillment operations that have already committed to mini-load ASRS technology and are seeking to upgrade their throughput capacity or replace older equipment with a more powerful and efficient model to handle growing volumes.

Performance Metrics

The provided content emphasizes best-in-class performance values and maximum efficiency as key metrics but does not list specific numbers (e.g., travel speed in m/s, cycles per hour). The "most powerful" and "lowest approach dimensions" are qualitative comparative metrics that define its position in the market.

Conclusion

The Jungheinrich STC 2B1A Miniload stacker crane is positioned as a premium, high-performance solution for businesses looking to push the limits of efficiency in their automated small-parts storage. Its value proposition hinges on delivering more throughput and energy savings per square meter than standard systems. For operations where mini-load ASRS is a critical bottleneck, upgrading to a more powerful crane like the STC 2B1A could be a justified investment to unlock additional capacity and reduce operating costs. Potential users should engage with the supplier to obtain detailed performance data and conduct a site-specific analysis to validate the claimed benefits against their unique operational and financial models.