Quick Facts

Key Statistics

Geographic Coverage

- • High-density AutoStore grid with 34,000 storage bins and 54 robots

- • Integrated FulfillX software for workflow optimization and order expediting

Cutter & Buck Seattle Apparel Fulfillment Center

Cutter & Buck deployed an AutoStore system with 34,000 bins and 54 robots, implemented by Kardex, to streamline apparel fulfillment, reduce storage footprint by 50%, and achieve order turnaround in under 10 minutes.

- • Eight Vertical Buffer Module Kardex Compact Buffers with automatic inbound system

- • Integrated conveyor network connecting receiving, storage, and shipping zones

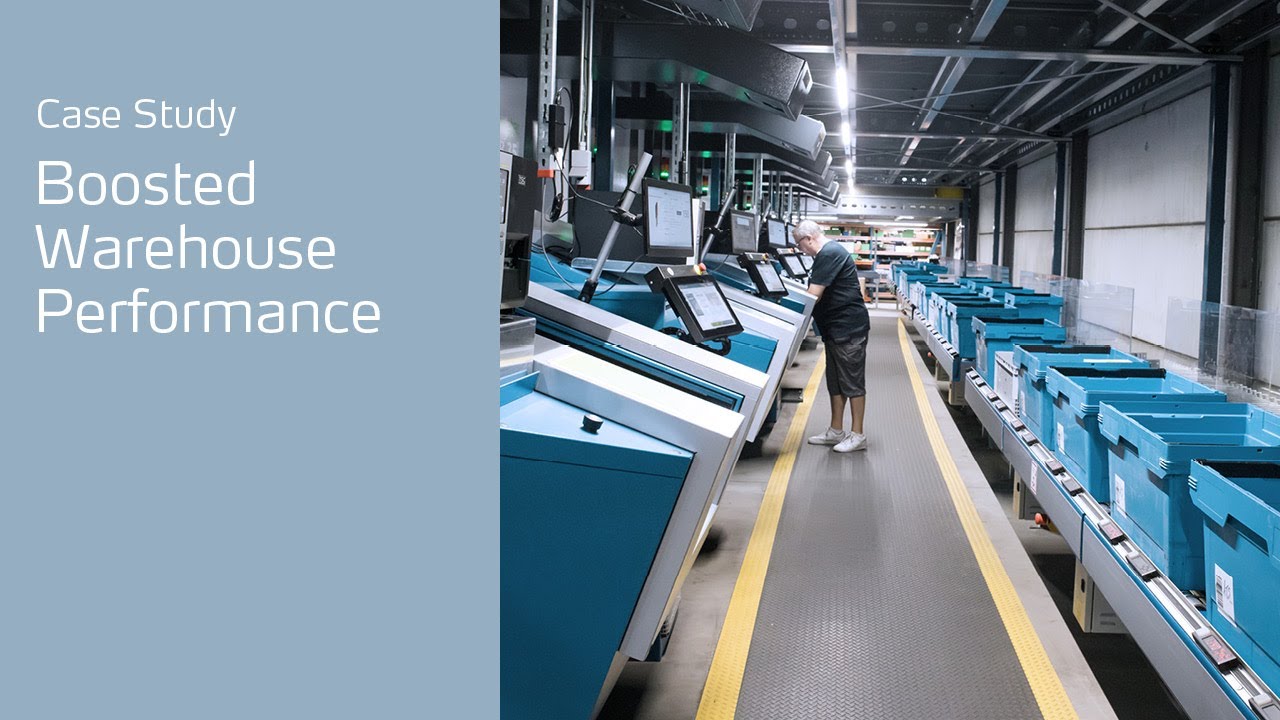

ATS Group - Merelbeke Belgium Electrical Components Automated Warehouse

ATS Group implemented Kardex's 8 Vertical Buffer Module system with automated inbound and conveyor integration, saving over 50% floor space while increasing throughput from 500 to 900 orders.

- • Cross-building design with AutoStore grid and picking ports separated by a wall

- • Utilization of seismic bracers instead of support columns to maximize floor space

Balluff Inc. Sensor Solutions Automated Warehouse

Balluff Inc. achieved a 177% throughput increase with an AutoStore system implemented by Kardex, featuring an innovative cross-building design installed in just 6 months.

- • Five Kardex Miniload-in-a-Box systems: two for small parts, three 18-meter extended versions for full bin picking

- • Extended VBM units doubling storage capacity with minimal performance impact

SHAKE-HAND - Belgian Standard Elements Automated Storage

SHAKE-HAND implemented Kardex Miniload-in-a-Box systems including extended VBM units to replace manual storage, doubling capacity and reducing picking errors for machine builder distribution.

- • 18 Kardex vertical lift modules (VLMs) maximizing vertical space utilization to full ceiling height

- • Integrated conveyor system optimizing material flow and reducing manual handling

Van Meter - Cedar Rapids Electrical Distribution Warehouse Automation

Van Meter implemented 18 Kardex vertical lift modules and conveyor systems to automate electrical parts distribution, achieving 99.99% accuracy and supporting business growth goals.

Technology Expertise

Industry Experience

Service Capabilities

Company Overview

Kardex was founded in 1898 in Zurich, Switzerland, initially as Rand Kardex Bureau AG in 1922 but with roots dating back to 1898. The company has evolved into a leading global provider of automated storage solutions and material handling systems, listed on the SIX Swiss Exchange since 1989. As a public company, Kardex maintains an integrated management system with certifications in quality, environment, energy, occupational management, and information security.

With approximately 2,900 employees in over 30 countries and annual revenue of €791 million as of December 31, 2024, Kardex holds a strong market position in intralogistics, specializing in premium automated products, standardized systems, and life cycle services. The company's scale is highlighted by its production facilities in Germany and a focus on high availability and low total cost of ownership.

Kardex's core value proposition is offering intelligent entry into automation with dynamic storage and retrieval systems, integrated material handling, and flexible modular solutions like AutoStore. Key differentiators include its commitment to innovation through partnerships, a global network for tailored implementations, and a emphasis on sustainability and efficiency in intralogistics.

Core Capabilities

Technology Solutions

Kardex offers a comprehensive portfolio of automated storage solutions, including Vertical Lift Modules (VLMs) for efficient bin and tote storage, fully integrated AutoStore systems for flexible and modular storage and order fulfillment, and the Intuitive Picking Assistant (IPA) for enhanced order picking accuracy and productivity. Heavy and oversized load handling solutions address specific needs in manufacturing, while robotics integration with partners like Berkshire Grey provides advanced picking capabilities.

The technology approach emphasizes space optimization, reducing search times, and improving operational efficiency through automation. Features include QuickShip Program for rapid VLM deployment, Kardex Analytics for data insights, and scalable systems that adapt to varying complexity levels from standard to customized.

Industry Expertise

Kardex serves diverse industries, including manufacturing with solutions for heavy loads at MAHLE, e-commerce and retail for high-volume fulfillment, 3PL/logistics for distribution facilities like Van Meter, food & beverage for perishable storage, fashion/apparel for omnichannel operations, automotive for parts handling, and healthcare/pharma for compliant environments. Specific expertise includes clean room classifications from EN-ISO 5 to 8 and optimizing storage for electronics and industrial sectors.

Notable achievements involve increasing throughput by 25% and reducing labor costs by 21% for MAHLE, automating electronics distribution for Van Meter, and enhancing productivity in 3PL facilities.

Service Approach

Kardex's service model includes consulting for warehouse modernization, system design, implementation, integration, project management, installation, training, on-site service, remote support, maintenance, modernization, and spare parts. The methodology involves experienced specialists guiding from planning to implementation, with tailored telephone support options like 24/7 hotline.

The service philosophy is focused on high availability and low total cost of ownership through life cycle services. Geographic coverage spans over 30 countries with local contacts for responsive support.

Competitive Advantages

- Global Automation Leadership: Kardex provides premium automated products and life cycle services that guarantee high availability and low costs, serving over 30 countries with 2,900 employees.

- Innovative Partnerships: Through collaborations with AutoStore and Berkshire Grey, Kardex offers flexible modular storage and robotic picking, enabling scalable solutions for diverse industries.

- Sustainability and Efficiency: The company's systems optimize space and reduce search times, with certifications like ISO 50001 for energy management and focus on ergonomic designs.

- Tailored Life Cycle Services: Kardex delivers end-to-end support from modernization to 24/7 maintenance, ensuring long-term reliability and adaptability.

- Industry-Specific Expertise: With solutions for clean rooms and heavy loads, Kardex addresses unique challenges in manufacturing, healthcare, and e-commerce for enhanced productivity.

Global Presence

Kardex operates in over 30 countries across North America, Europe, Asia Pacific, Middle East, and Latin America, with headquarters in Zurich, Switzerland. The office network includes production facilities in Bellheim and Neuburg an der Kammel, Germany, and regional offices in Atlanta, USA; Sydney, Australia; Singapore; and Schwerzenbach, Switzerland. This footprint enables localized sales, implementation, and service, supporting a global customer base with responsive teams.

Innovation & Technology

Kardex focuses on R&D to transform tradition into innovation through agile methodologies and market-driven developments. Emerging technologies include AI-enhanced picking and robotic integration for intralogistics. The innovation philosophy emphasizes collaboration and strategic partnerships with companies like Zühlke Group and Avencore. Recent technological advances feature the next generation of automation technology unveiled in 2025 and expansions in robotic solutions for semiconductor and electronics industries.

Typical Project Profile

Project Types:

- Automated storage implementations for manufacturing parts handling

- Omni-channel fulfillment centers for e-commerce and retail

- Warehouse modernization with ASRS for 3PL distribution

- Clean room automation for healthcare and pharma

- Heavy load storage systems for automotive Typical Timeline: Varies by project scope Implementation Approach: Experienced specialists guide from planning to implementation, with joint concept development, installation, ramp-up, and ongoing OnSite support for performance optimization.

Why Choose Kardex

Kardex stands as a trusted global partner for intralogistics, offering innovative automated storage solutions that optimize space and efficiency. Customers benefit from tailored life cycle services and strategic partnerships that ensure low total cost of ownership and high availability.

Related Technologies

- Unit Load AS/RS

- Mini-Load AS/RS

- Shuttle Systems

- Goods-to-Person Systems

- Robotic Palletizer

- WMS, WES, WCS

Research Notes:

- Information gathered from: https://www.kardex.com/, https://en.wikipedia.org/wiki/Kardex_Group, https://www.kardex.com/en/certifications, blog.kardex-remstar.com/case-studies, https://technologymagazine.com/company-reports/kardex-transforming-tradition-into-innovation, https://www.kardex.com/en/company/kardex-locations, various case studies and financial reports

- Logo URL verified: Yes

- Last updated: January 03, 2026

- Confidence level: High

- Any information gaps: Specific project completed numbers not found; exact revenue for 2026 estimated from 2024 data; typical timelines not detailed on site